All necessary fittings are supplied for standard installation, except for the final fitting into the oil sump which you need to make a banjo bolt and certain thread sizes for the pressure sending unit. If any additional fittings are needed for any special applications, contact us or any authorized GLW dealer for further assistance.

1) Take out the oil sump nut and drain out all the engine oil before proceeding with installation of the pressure switch fittings.

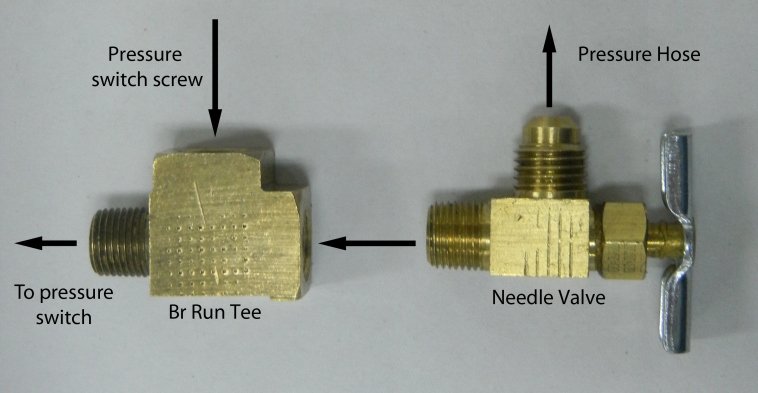

2) Locate and remove the pressure switch screw from the engine and install the supplied Br Run Tee connector in its place. The oil pressure sending unit is usually a small device screwed into the engine block with wire connected to it. They are usually mounted near the factory full flow filter.

3) Install the pressure switch screw into one of the two remaining holes of the Br Run Tee using pipe sealant and tighten securely. Use the hole in the Br Run Tee which gives you the easiest access.

4) Install the needle valve (one side of which will be 1/8” JIC male) into the remaining thread hole of the “T” and tighten securely. (See Example 1, Example 2 here)

5) Install the Br Hex Bushing, Non-return valve, Br Adaptor and Pressure hose fittings to the FS canister as shown above. Depending on the location of your FS canister, you may need to insert a 45 or 90 degree elbow fitting. The elbow fitting can be inserted between the Br Non-return valve and Br Adaptor.